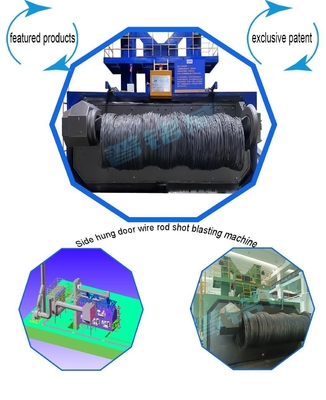

Single Mandrel Wire Rod Coil Shot Blasting Machine with After-sales Service

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, HSE, QC 080000, BSCI |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: 1-3 months |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 500 Sets Per Years |

|

Detail Information |

|||

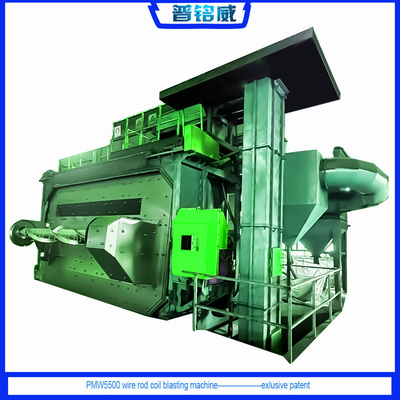

| Model NO.: | By Trial Blasting Machine | Colour: | Blue |

|---|---|---|---|

| Ramming Head: | Six | Application Scope: | Wire Rod |

| Transport Package: | Sea Transportation | Specification: | 6.6× 5.5× 6m |

| Trademark: | Pumingwei | Origin: | Jinan, China |

| Supply Ability: | 120 | Customization: | Available |

| After-sales Service: | First-Class Service | Warranty: | Year |

Product Description

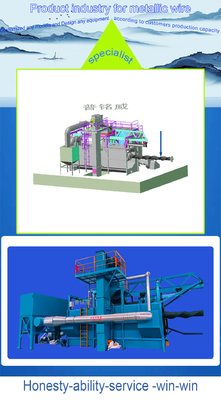

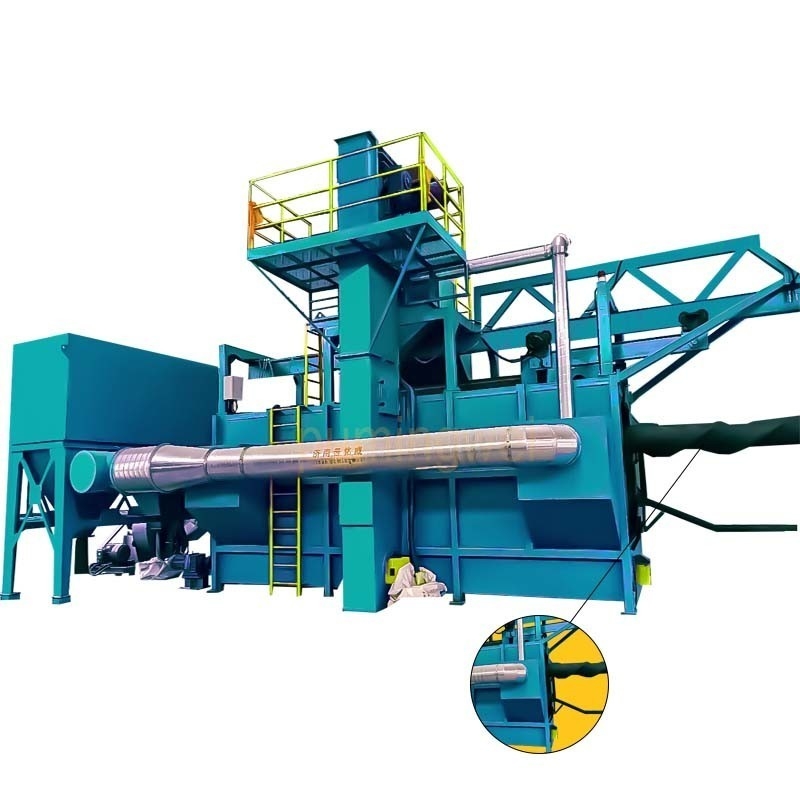

PMW 5000D wire rod shot blasting machine adopts a unique "auto retractable cantilever shaft" to carry the wire working mode. The cantilever shaft is made of special alloy steel.which greatly improves the service life of the shaft .It is also a patented product of our company (patent No. : 201620372463.5). In the process of shot, the device makes wire do compound action of up and down + side to side + positive and negative rotation to achieve the effect of thorough cleaning. The reasonable arrangement of impeller head have resulted in effective blasting of steel shot in the inner and outer surfaces of wire,the machine is controlled by PLC, and the operation is convenient and reliable. This machine has the function of automatic dispersing wire, therefore, save the work of manual working, reduce labor intensity and improve work efficiency.

1.Environmentally-friendly technology instead of pickling.

2.Remote control,easy operation.

3.To disperse the wire automatically,even,high effective

and lowl abor intensity for operator.

4.Ultra-low emission:3mg/m³.

5.Widely used in (high,medium,low) carbon steel,alloy

steel,stainless steel and others.

6.Good work environment and negative pressure

within equipment.

7.Can be customized according to customer products.

8.Retractable shaft with exclusive patent.

The equipment is equipped with 5sets impeller head according to the characteristics of wire rod,which is installed on the rear/side of the shot blasting chamber to clear the wire with 60-90secs cast speed,.By using screw horizontal conveying shot system, high strength belt hoist, steel shot residue separation system, two-stage purification dedusting system (inertia + filter ) and (automatic + manual )HMI electric control system,it makes the workpiece meets efficient shot blasting requirements. ![]()

| Application range | fasteners,wire rope,spring,stainless steel,welding rod,cold-heading wire,etc. |

| Production capacity | 20,000-80,000 each year |

| Wire diameter | 8-42mm |

| Equipment size | 6.6*5.5*6m(height on the ground) |

| Wire loss | 0.2-0.3% |

| Derusting cost | about20-40RMB/T |

| Production efficiency | 2-4coils/per hour |