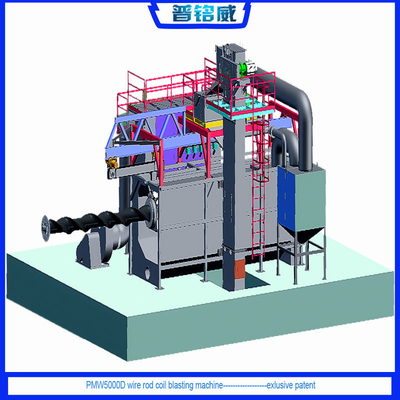

Customizable Hanging Retractable Wire Rod Shot Blasting Machine with Exclusive Patent

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, HSE, QC 080000, BSCI |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: 1-3 months |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 500 Sets Per Years |

|

Detail Information |

|||

| Model NO.: | 5000D | Produce: | 1--4ten Thousandt |

|---|---|---|---|

| Wire Diameter: | 6.5--42mm | Cost: | 40--20RMB |

| Transport Package: | Sea Transportation | Specification: | 9*4*5.8m |

| Trademark: | Pumingwei | Origin: | Jinan, China |

| Supply Ability: | 120 | Customization: | Available |

| After-sales Service: | First-Class Service | Warranty: | Year |

Product Description

Equipment name: Single station full coil round wire shot blasting cleaning machine Equipment model: PMW-5000D

Introduction:This machine is a specialized equipment for cleaning circular wire rods, which uses the shot blasting process to remove the oxide skin on the surface of the wire rods. The workpiece has been shot blasted and cleanedAfter that, the surface rust removal level reaches Sa2.0-3.0, and the inside and outside are uniform and free of scratches. Compared with acid pickling treatment, it is economical,The characteristics of environmental protection and efficiency.The equipment adopts a unique "fixed cantilever shaft" to carry the circular wire working mode. The cantilever shaft is made of special alloy steel,The cantilever shaft outer sleeve is a special device with automatic material scattering function, which forms an integral part with the cantilever shaft group during normal operation

The composite action of "downward undulation+left and right swing+forward and backward rotation" is used to achieve a thorough cleaning effect. The cantilever shaft is made of special alloy steel

The production greatly improves the service life of the spindle. Reasonable layout of the shot blasting device ensures that both the inner and outer surfaces of the coil wire can be

Effectively hit by bullets, controlled by PLC for easy and reliable operation. This machine has the function of automatic material dispersion, therefore

During work, it can eliminate manual bulk material work, reduce labor intensity, and improve work efficiency.

| Application range | fasteners,wire rope,spring,stainless steel,welding rod,cold-heading wire,etc. |

| Production capacity | 10,000-40,000 each year |

| Wire diameter | 6.5-42mm |

| Equipment size | 9*4*5.8m |

| Wire loss | 0.2-0.3% |

| Derusting cost | about20-40RMB/T |

| Production efficiency | 2-4coils/per hour |