Customized Hook Shot Blasting Machine Tailored to Meet Your Work Piece Requirements

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, HSE, QC 080000, BSCI |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: 1-3 months |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 500 Sets Per Years |

|

Detail Information |

|||

| Model NO.: | Q3710 | Fuel: | Electric |

|---|---|---|---|

| Type: | Hook Type Abrator | Cleanliness: | High Cleanliness |

| Automation: | Automatic | Feature: | Cleaning Workpiece Surface |

| Condition: | New | Customized: | Customized |

| Color: | Yellow And Blue | Single Hook Weight: | 10000kg |

| Shot Blasting Rate: | 8*270kg/Min | Total Power: | 180kw |

| Transport Package: | Foam, Pallet Or Customized | Specification: | Customized |

| Trademark: | Pumingwei | Origin: | China |

| Supply Ability: | 300sets/Each Year | Customization: | Available |

| After-sales Service: | One Year | Warranty: | One Year |

Product Description

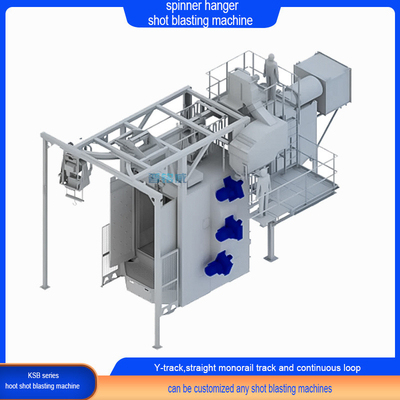

K series spinner hanger shot blasting machine

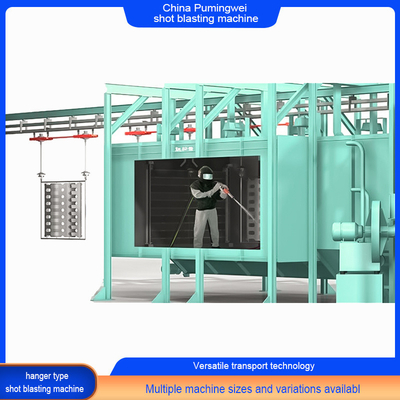

The standard overhead conveyor or spinner hanger shot blasting machines are specially developed for cleaning the surface of a wide range of work pieces. Shot blasting or grit blasting is a metal finishing process used either for preparing the surface for further processes or as a final surface finishing method. When the surface is blasted with abrasive media at high speed inside a blast cabin, the abrasive media or also known as blast media will impart the required roughness for further deposition process or remove unnecessary impurities and make the surface clean and uniform texture/tone. The pieces to be blasted are suspended either one by one or bunch-like by means of hangers fitted to trolleys sliding along a monorail. The movement of the rail trolley is automatic from the inlet position through a conveyor system inside the blast cabin. The operator thus can stay outside and away from the cabin.

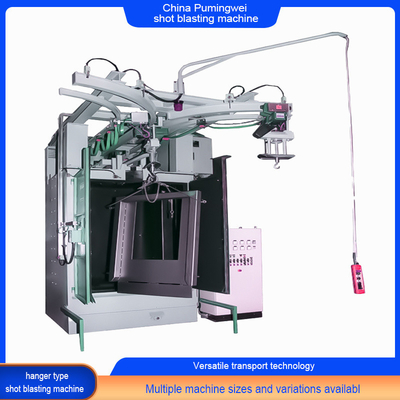

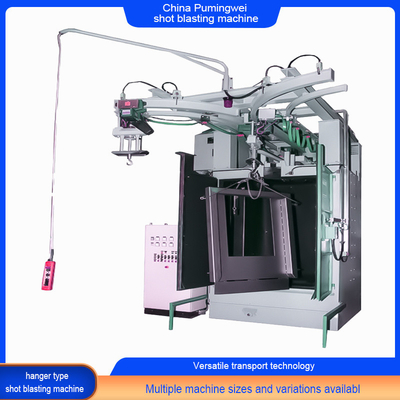

Q37series spinner hanger shot blasting machine

Hook type shot blasting machine is divided into two forms,:single hook type and double hook suitable for surface cleaning or strengthening with small and medium-sized castings, forgings, welding parts, heat treatment parts in various industries .especially suitable for cleaning and strengthening for fear of collision parts. It adopts the forms of no pit structure with compact structure, easy installation and smooth operation.

The electric hoist is used to realize the loading and unloading, lifting and walking of the workpiece, and positive and negative rotation of the workpiece inside chamber is available by the auto rotation device.

Paramete Type | Q375 | Q376 | Q378 | Q378A | Q378E | Q379 | Q3710 |

| The max single hook weight/kg | 500 | 500 | 800 | 800 | 800 | 1000 | 1000 |

| The max castings size/mm | 1000*1400 | 800*1100 | 800*1500 | 1000*1800 | 1400*1500 | 900*1500 | 1100*2500 |

| Cleaning room size/m | 1.6*1.6*2.15 | 1.6*1.6*2.15 | 1.6*1.6*2.15 | 2.0*2.0*2.75 | 2.0*2.0*2.2 | 2.0*2.0*2.1 | 2.0*2.0*2.5 |

| Production rate | 4-15 | 6-15 | 4-9 | 6-12 | 4-15 | 6-15 | 6-15 |

| Dedusting air volume(m3/h) | 9700 | 2000 | 6000 | 7500 | 5500 | 6600 | 9900 |

| processing capacity of separating system/(t/h) | 20 | 15 | 25 | 25 | 40 | 35 | 45 |

| Impeller head quantity | 2 | 1 | 2 | 2 | 2 | 2 | 3 |

| Single abrasive flow rate(kg/min) | 140 | 220 | 200 | 200 | 240 | 250 | 230 |

| power per blasting wheel/kw | 7.5 | 11 | 11 | 11 | 15 | 15 | 11 |

| Total power/kw | 27.3 | 20 | 27.4 | 30.5 | 39.6 | 35.6 | 55.5 |

| Overall dimension/mm | 6.37*3.3*5.5 | 6.3*3.2*4.8 | 4.4*3.93*6.42 | 6.0*3.76*7.308 | 5.6*6.1*6.65 | 4.47*3.315*5.365 | 4.809*2.825*7.118 |

| Machine Description | KSB-10 | KSB-25 | KSB-25A | KSB-50 |

| Cleaning Capacity: Max Work Size (Dia. X H) | 47" x 59" (1,194mm x 1,499mm) | 59" x 78" (1499mm x 1981mm) | 78" x 98" (1981mm x 2489mm) | 98" x 118" (2489mm x 2997mm) |

| Cleaning Capacity: Max Hanger Load | 1 ton (907kg) | 2.5 ton (2268kg) | 2.5 ton (2268kg) | 5 ton (4536kg) |

| Blast Wheel: Model | Y-30 | Y-30 | Y-30 | Y-30 |

| Blast Wheel: Qty x HP | 2 x 15 | 3 x 15 | 4 x 15 | 5 x 15 |

| Type | QGW20-50 | QGW80-150 |

| Clearing pipe diameter size | 30-500 | 250-1500 |

| Abrasive flow rate | 2*260(kg/min) | 2*260/2*750(kg/min) |

| Clearing speed | 0.5-4(m/min) | 0.5-4/1-10(m/min) |

![]()

![]()

![]()

![]()

![]()

![]()