Fast Shipping Wire Rod Coil Shot Blasting Machine with High Cleanliness and Automation

Product Details:

| Place of Origin: | China |

| Certification: | ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, HSE, QC 080000, BSCI |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiable |

| Delivery Time: | Peak Season Lead Time: 1-3 months Off Season Lead Time: 1-3 months |

| Payment Terms: | LC, T/T, D/P, PayPal, Western Union, Small-amount payment |

| Supply Ability: | 500 Sets Per Years |

|

Detail Information |

|||

| Model NO.: | PMW5300 | Fuel: | Electric |

|---|---|---|---|

| Type: | Rotary Abrator | Cleanliness: | High Cleanliness |

| Automation: | Automatic | Feature: | Rust / Corrosion Proof |

| Condition: | New | Customized: | Customized |

| Work: | Shot Blasting Machine | Transport Package: | Nuded Cargo |

| Specification: | 16.8X12.4X5 Meter | Trademark: | Pumingwwei |

| Origin: | China | HS Code: | 8424300000 |

| Supply Ability: | 2000PCS Per Years | Customization: | Available |

| After-sales Service: | One Years | Warranty: | One Years |

Product Description

Ensuring the normal, safe and smooth working of the equipment must meet the following working conditions.

1.The workshop must have a ≥5T double hoist crane, the distance from the beam to the ground shall not be less than 6 meters.

2.Power supply:AC380V 50HZ Total power ~ 287KW

3.Equip with a 2m³, 0.8MPa air storage tank

4.No strong magnetic interference source around the workshop

5.Maintain the equipment according to the manufacturer's instruction

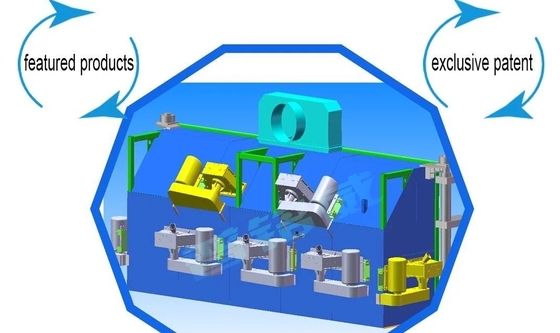

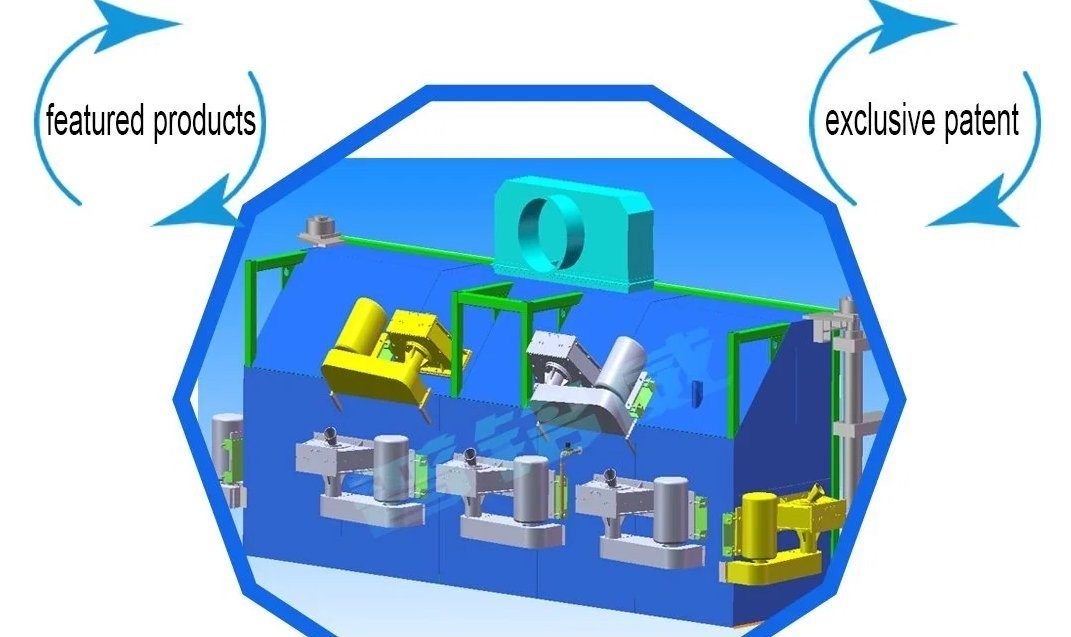

working principle for PMW5300 wire rod coil shot blasting machine

The equipment adopts the unique double "side hung gate + pin-ended "to carry the form of the wire rod, which is the patent product of our company (the patent number:(201520774091.4)operation adopt double-position form,bring two workpieces alternant working .

When the simple supported shaft of the wire rod enters the blasting room,which open the steel shot controller to covey steel shot to rotating impeller head,throw out the steel shot with high speed bade to hit wire rod with certain angles,which make its oxide, the Lin layer and its debris fall off. At the same time ,perform compound action "ups and down, right and left positive and negative rotation" by programmed program to beat the inside and outside surface of wire rod with steel shot effectively. The reasonable distribution of the 7 impeller head makes the whole wire rod without corners.

Product Parameters

| Application range | fasteners,wire rope,spring,stainless steel,welding rod,cold-heading wire,etc. |

| Production capacity | 70,000-150,000 each year |

| Wire diameter | 5.5-42mm |

| Equipment size | 16.8*12.4*5.8m(overground height) |

| Wire loss | 0.2-0.3% |

| Derusting cost | about15-35RMB/T |

| Production efficiency | 4-10coils/per hour |

QPY5325 type wire rod shot blasting machine is a special equipment which cleaning wire rodm,which convert the kinetic energy of the steel shot in high speed flying into the impact force of workpiece surface to strip the oxide and impurities on base metal by using the plastic deformation of the base metal and its oxide, thereby cleaning the wire rod surface thoroughly.The rust removal level of surface after wire rod postprocessing reaches Sa2.0-2.5.

As the cleaning technology of this equipment,there is no chemical reaction , its byproduct is recyclable metal scrap, so this technology is green environmental protection and no pollution.It has the characteristics of economy, environmental protection and high efficiency compared with the traditional pickling method.Therefore, this equipment is widely used in the spring, bolt, welding rod, welding wire, steel wire rope,steel strand,etc. Which get more customers favor on smoggy day

![]()

![]()

![]()

![]()

![]()

Leader Wang / Jinan Pumingwei Electrical Equipment Co. Ltd

552 Gongye Er Road, Mingshui Street, Zhangqiu District, Jinan, Shandong, China

North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe